Do You Have A Process Issue We Can Help With?

Available Plastic Additives

At Phoenix Plastics, we can meet all of your plastic additives needs in one place! Take a quick look at our products below. You’ll certainly find what you need, and you may discover something you never knew could make your production process simpler.

Applications: Injection Molding – Pipe/Profile

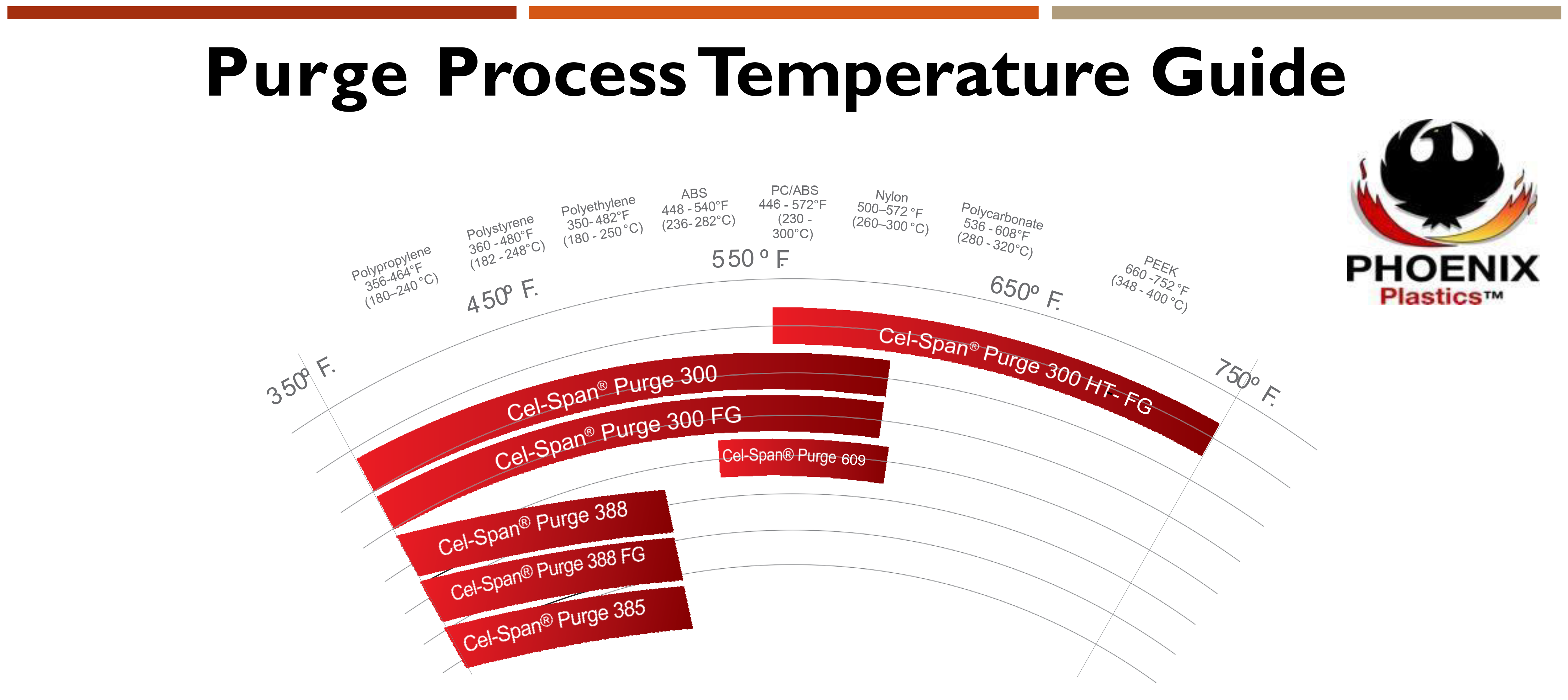

Temperature Range: 350°F – 600°F (177°C – 315°C)

Melt Flow: 0.3-0.5 HDPE (grams/10 min.), at 190°C

Blend Density: 0.955 g/cc

Types of Resins: PE, PP, PS, PA, POM, ABS, and PC/ABS

Amount Required: 1 – 3 times barrel capacities suggested. (Amount may vary by machine)

Applications: Injection Molding – Pipe/Profile

Temperature Range: 350°F – 600°F (177°C – 315°C)

Melt Flow: 0.3-0.5 HDPE (grams/10 min.), at 190°F

Blend Density: 0.955 g/cc

Types of Resins: PE, PP, PS, PA, POM, ABS, and PC/ABS

Amount Required: 1 – 3 times barrel capacities suggested, but actual amount depends on machine conditions

Applications: Injection Molding – Blow Molding – Pipe/Profile Sheet

Temperature Range: 350°F – 500°F (177°C – 260°C)

Melt Flow: 1-10 HLMI (grams/10 min.), at 190°C/21.6kg

Blend Density: 0.955 g/cc

Types of Resins: PE, PP, PS, PA,

Amount Required: 1 – 3 times barrel capacities suggested, but actual amount depends on machine conditions

Applications: Injection Molding – Blow Molding – Pipe/Profile Sheet

Temperature Range: 350°F – 500°F (177°C – 260°C)

Melt Flow: 1-10 HLMI (grams/10 min.), at 190°C/21.6kg

Blend Density: 0.955 g/cc

Types of Resins: PE, PP, PS, PA,

Amount Required: 1 – 3 times barrel capacities suggested, but actual amount depends on machine conditions

All of our chemical foaming agents are manufactured in house using our process technology. Our selection of CFA’s come in a variety of resin carriers and various loadings in order to achieve a gas volume requirement.

Our widest and broadest category of masterbatches are tailored toward polyolefins, nylons and other engineered resins. If you need flow enhancement, increase productivity, dispersants, mold release or to eliminate die build up, we have a product that will meet your specific needs.

Applications: Injection Molding

For best results, laboratory tests or preproduction trials should determine the optimum additive level. Cel-Span® Process Aid 101 internal lubricant is effective within a range of 1 to 10 parts per 1000 resin excluding reinforcements such as pigments and fillers. A high amount of filler may require a higher percentage of internal lubricant. Always start an evaluation at 5 parts per 1000 (0.5%). The internal lubricant may increase the melt flow index (MFI). Reduce the level of Cel-Span® Process Aid 101 or reduce the process temperature to raise the resin viscosity and eliminate screw slippage.

Cel-Span® Process Aid 606C recommended usage level is 1.0% to 2.0%. Since the carrier resin for Cel-Span® Process Aid 606C is polycarbonate, we recommend drying which is typical when using polycarbonate resins. For injection molding processes, adjust machine conditions so that the work energy is maintained in the screw. We also recommend that the rear zone temperatures be reduced by 15 – 20% and the front zone by 5 – 10%.

All polymer chains must be protected or risk decomposition breakdown. We offer a wide selection of thermal, ultraviolet and anti-oxidant stabilizers to tailor to your process and resin system.

Phoenix makes several varieties of non-nitrated VCI masterbatches that offer multi metal corrosion protection. Our VCI masterbatches meet most automotive specifications and we offer third party testing.

We offer several antimicrobial masterbatches with unique additives depending on your end use, process and resin system.

Our GAIA® products are in a masterbatch form for repelling of insects in the agricultural market. We also have the ability to compound highly loaded fragrances and essential oils to fit your needs.

We have a complete line of oxo-degradable and PLA based degradable additives for film and injection molding systems.

Phoenix Plastics offers a complete line of flame retardants compounds and concentrates based on magnesium hydroxide, intumescent chemistry, and brominated systems.

The Plastic Additives You Need

We at Phoenix Plastics have over 200 products, so we’re sure to have the product that fits your company’s specific needs. Contact us today to find the additive that fits your manufacturing process. We also provide small and large batch specialty tolling services.

After the Sale

Since we manufacture our products on site, we’re also able to save you money on shipping. You’ll get them directly from us, and you can rest assured that our shipping rates are among the best in the industry.

At Phoenix Plastics, we don’t believe the transaction is over just because you’ve received your products, so if you ever have any questions, don’t hesitate to ask.

ABOUT US

Located in Conroe, TX, just north of Houston, Phoenix Plastics was founded in 1996 but our staff has more than 75 years of experience in the plastic industry. Our testing and processing takes place in-house, which allows Phoenix Plastics to maintain high quality standards. Phoenix Plastics is an ISO:9001 certified company.

CONTACT US TODAY

5400 Jefferson Chemical Rd

Conroe, TX 77301

1.866.760.2311 / Fax: 936.760.2322

phoenix@phoenixplastics.com

Location Hours:

Monday – Friday: 8:00 AM – 4:00 PM CST

Dock Hours: Monday – Friday: 9:00 AM – 3:30 PM CST