Did you know that the true genius of chemical foaming agents is found in partial foaming? This is where you foam your product “Just a bit” to overcome your process or product issues. At the same time, most operators also find that partial foaming products can bring additional and highly-welcomed savings. Once again, Phoenix Plastics has provided vital resource information below to help keep your operations running smoothly and efficiently. Read on to discover more.

Benefits of Partially Foamed Products

Most people have learned to take advantage of a great thing when they understand and value the benefits behind it. This same thing applies to partially foamed products. With partial foaming, you can:

- Increase shot speed

- Reduce cycle time

- Improve Impact resistance

- Lower part stress and warpage

- Increase dimensional stability

- And also remove sink marks

- Off Spec parts can be recycled

Why Consider Foaming My Product(s)?

Save Money

Ultimately, the most common reason to consider foaming your product is to save on costs. You can save money and not have to worry about hindering key properties of your product. At the same time, you can also reduce the weight of your products up to 5-20 percent for conventional plastic injection molding equipment. Less weight means less cost.

See Where You Save

In order to see where you save, you must know the 5% Rule. That is, ‘if you can save 5% on materials you’ve already paid for the additive’. Then, any savings after that initial 5% is money back in your pocket. Thus, you save in materials, and you use less energy to process the same product.

Where Your Clients Save

Another great thing about foaming your product is that you can pass along a percentage of the cost savings to your clients. Transport for them will also be less costly (Weight reduction). Furthermore, if installation and handling is required it will entail a lot less effort.

Other Benefits You Should Know

Friendlier to the Environment

One major benefit to using partial foaming that most people don’t think about is the indirect benefit to the environment. You can help lower the carbon footprint of your facility. This is a result of utilizing less material and less energy to produce the same product. You also use less fuel for transport, and there is a lot less waste produced after its end life.

Myths About Chemical Foaming Agents

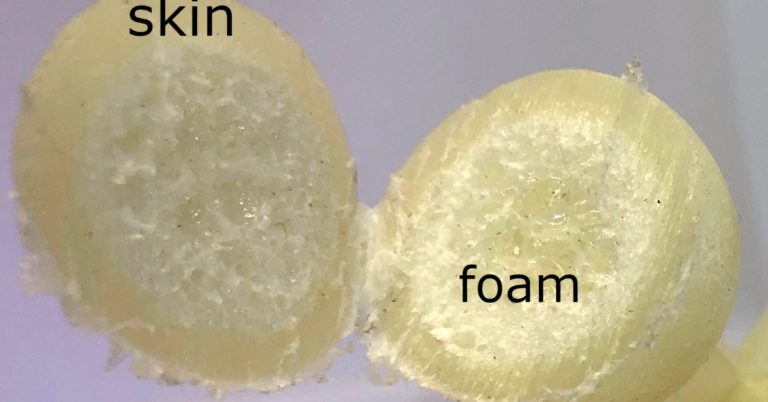

Myth 1 – Foamed products are lower quality. Here is the Truth – When you use the foaming agent specific to your product, then optimizing the process will create nice a high-quality foamed product.

Myth 2 – My product cannot be foamed. (It’s too thin or esthetic is important). The Truth – Some designs may not tolerate foam, but those circumstances happen much less often than previously thought. Likewise, you can even foam films when using the proper foaming agent and process conditions.

Looking for more information about foaming agents? Connect with our service team at Phoenix Plastics. We’re always happy to help. Call us toll-free at 1-866-760-2311!