Plastic is one of the most widely used materials in the world, but non-biodegradable plastic can take centuries to decompose. To address this, some plastic manufacturers have introduced biodegradable plastic additives that make plastic more eco-friendly by accelerating its breakdown.

Here’s what you need to know about degradable additives with traditional plastics, how they work and what they do, and discuss their advantages and disadvantages for different applications.

Process and Lifespan of Traditional Plastics

How long does it take plastic to biodegrade? Traditional plastics are usually made from petroleum and petroleum by-products. When formed, it can take hundreds, if not thousands, of years to degrade. This is because the plastic composition is highly resistant to the normal forces that cause degradation, including light, moisture/humidity, air, bacteria, and fungi, which can all separate plastic polymers and make them fall apart.

While it is beneficial to have something that lasts a very long time, it also means that plastic stays in the environment for a long time. Degradable additives address this problem by making plastic biodegradable, among other options.

Process and Lifespan of Plastics Made from Degradable Additives

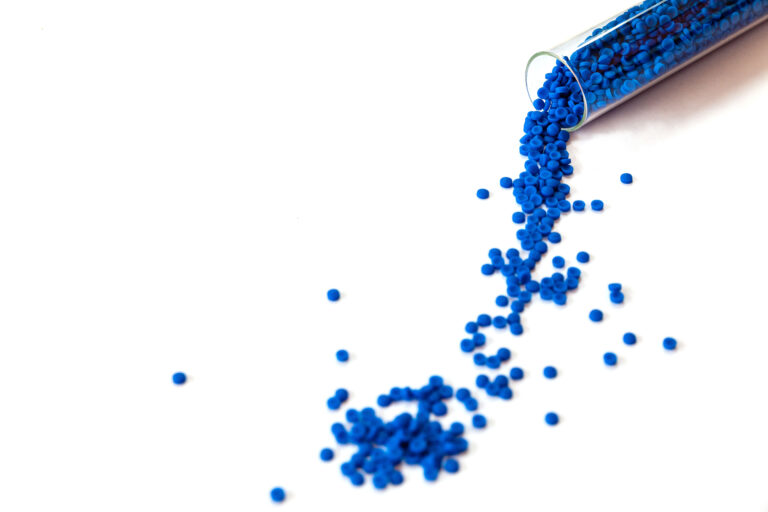

Degradable additives are mixed into plastic to change its properties. The goal is to make the plastic degrade quickly under the right circumstances.

The right mix of degradable additives can keep plastic from creating environmental problems, making it more sustainable. For example, oxo-degradable additives can help plastic break down in the presence of oxygen.

Challenges and Limitations of Traditional Plastics

Traditional plastics present significant challenges, particularly in terms of disposal and environmental impact. One of the most pressing issues is their extremely slow decomposition rate, with some plastics persisting in the environment for hundreds or even thousands of years. This durability leads to the accumulation of plastic waste in landfills, oceans, and natural ecosystems, contributing to widespread pollution and harming wildlife and ecosystems.

Challenges and Limitations of Degradable Additives

While degradable additives can help with the problems of traditional plastic, they can create other problems. For example, having an additive that causes degradation in the presence of moisture and heat can be great for plastic used in a sealed, climate-controlled space. However, it can lead to a catastrophic failure if used in a place that is always hot and humid.

Benefits of Degradable Additives

Degradable additives help resolve the most prominent problem associated with using plastic: the time it takes to decompose. If made correctly, traditional plastic turns into bioplastic, which is much better for the environment. It could substantially decrease the problem of plastic pollution.

In certain applications, bioplastic can help in engineering projects. Predicting how a material breaks down can help in engineering projects. Developers can better manage projects.

How to Choose When to Use Degradable Plastic Additives

Use degradable plastic additives in cases where the plastic will not be exposed to conditions that make it break down early. This means keeping plastic with degradable additives away from the sun, moisture, and other things that can cause degradation.

If you have the right conditions, you can use biodegradable plastic instead of traditional plastic. Otherwise, traditional plastic is the better option.

Alternatively, use traditional plastic in structural use cases where the conditions may change. This means any case where the plastic bears a load or heavy forces and could be exposed to the wrong elements over time without someone noticing, leading to hidden decay that can weaken and destroy plastic.

Make Your Next Order the Right Plastic for the Application

Before placing your next order for plastic with degradable additives, make sure it is the right choice for your application. Phoenix Plastics makes both traditional and degradable plastic for different applications. Contact us at (866) 760-2311 to order the right plastic and plastic additives for your applications.