Plastic is a mainstay in our society as it is used in an infinite number of products and applications. Plastics are formulated for their intended use. Plastics may contain some water that is formed in high-temperature molding and the water bubbles can cause holes and other defects, impacting the mechanical properties, quality, and appearance of the plastic products. The way to avoid these issues is with the use of desiccants. Desiccants work to remove water during processing, effectively eliminating the presence of air bubbles and other defects.

Desiccants Offered by Phoenix Plastics

Because of our long history manufacturing plastics, at Phoenix Plastics we know that products are not one size fits all. That is why we offer three different desiccant products:

Cel-Span Process Aid 740®. This product is for use in nylon and nylon-type alloys. This product

This product features great benefits as it is easy to use, no process changes are required, it can be used at the normal resin processing temperature and RPM speed, it is safe and non-hazardous, and offers a one-year shelf life.

Applications: Injection and Blow Molding, Pipe/Profile Sheet, Compounding, Film

Temperature Range: 350°F – 650°F

Melt Flow: 6.0 gm / 10 min. with 2160 wt at 190o C

Blend Density: 2.3 gms/cc

Types of Resins: Nylon and Nylon type alloys

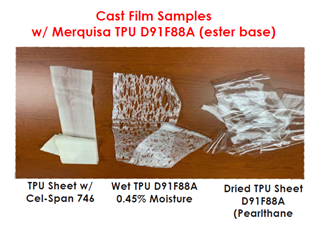

Cel-Span Drying Agent and Process Aid 746. This product is specifically for use in TPU resins.

This product features great benefits as it is easy to use, no process changes are required, it can be used at the normal resin processing temperature and RPM speed, it is safe and non-hazardous, and offers a one-year shelf life.

Applications: Injection & Blow Molding – Pipe/Profile Sheet – Compounding – Film

Temperature Range: 375°F – 450°F

Blend Density: 2.7 g/cc

Types of Resins: Polyurethane, Ether, and Ester

base plus Copolymers and alloys

Recommended Levels: 0.5 to 1.5% depending on moisture level in the host resin.

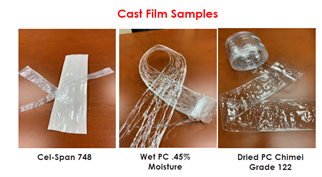

Cel-Span Drying Agent and Process Aid 748®. This product is used specifically for

This product features great benefits including ease of use, no process changes are required, it can be used at the normal resin processing temperature and RPM speed, it is safe and non-hazardous, and offers a one-year shelf life.

Applications: Injection & Blow Molding – Pipe/Profile Sheet – Compounding – Film

Temperature Range: 500°F – 575°F

Blend Density: 2.2 g/cc

Types of Resins: Polycarbonate and PC/ABS alloys

Recommended Levels: 0.5 to 2.5% depending on moisture level in the host resin.

Need Desiccants? Phoenix Plastics Can Help!

As you can see, Phoenix Plastics is very familiar with desiccants and we would be pleased to help you choose the right product for your specific compound. Simply contact us today and we will discuss your unique needs! We look forward to working with you soon!