Injection molding is one of the more popular processes commonly used in manufacturing. Because of its popularity, this process is popular when mass-producing your product. This process of molding has also become popular thanks to its sustainability in manufacturing, especially in the plastic injection molding industry. With injection molding and the proper plastic additives, it is possible to reduce toxic emissions and dangerous, non-disposable waste filling landfills. The trend for 2022 plastic molding will focus on using recyclable plastic materials to ensure sustainability. Today, we will be discussing how plastic additives are used in injection molding.

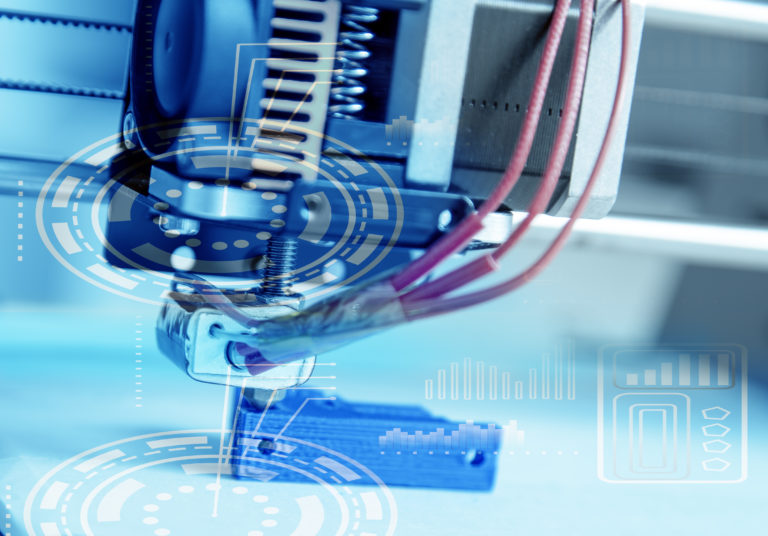

What Is Injection Molding, and How Does It Work?

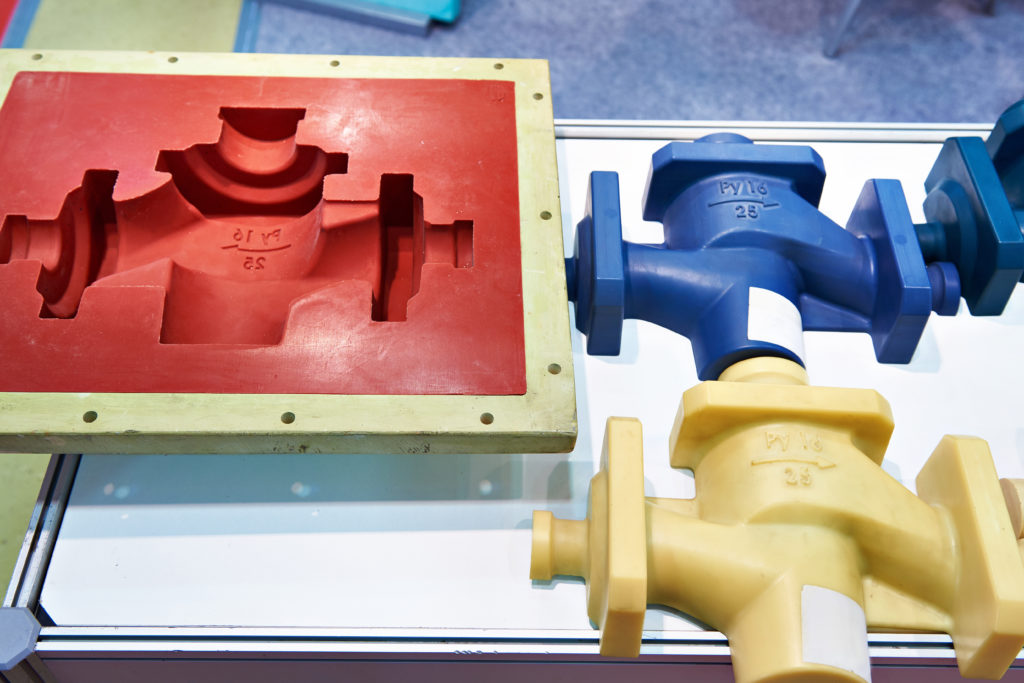

Injection molding is a manufacturing process for creating parts where melted plastic is injected into a mold. Once cooled, the plastic solidifies into the desired shape. Injection molding is a versatile manufacturing process that can create parts of various sizes and shapes. The process is relatively quick and easy, making it the ideal choice for mass production. As a result, injection molding is a highly versatile manufacturing process used to create parts for various applications.

The Different Types of Materials That Can Be Used in Injection Molding

Plastics and plastic additives are one of the most common types of material used in this process. However, injection molded parts can also be made from metals, plastics, and ceramics. Each type of material has its own unique set of properties that make it well-suited for specific applications. Metals are strong and durable, making them ideal for parts that will be subject to high levels of usage. Plastics are lightweight and easy to mold into complex shapes, making them ideal for precision. Also, Ceramics are heat-resistant and have a wide range of electrical and thermal conductivity. Phoenix Plastics is dedicated to providing the very best plastic additives for your manufacturing process.