Just like our skin, plastics are sensitive to the sun and its damaging UV rays, making UV protection vital. Extended exposure to sunlight and harsh outdoor environments can break down the chemical bonding of plastics, leading to discoloration and weakening of the material. Fortunately to combat the harmful effects of UV radiation on the appearance and physical characteristics of plastics, you can use UV stabilization. It’s one of the most efficient strategies for protecting polymer resins from the corrosive effects of UV radiation. Keep reading to learn more about the industry standards for plastic UV protection.

What Is Plastic UV Protection?

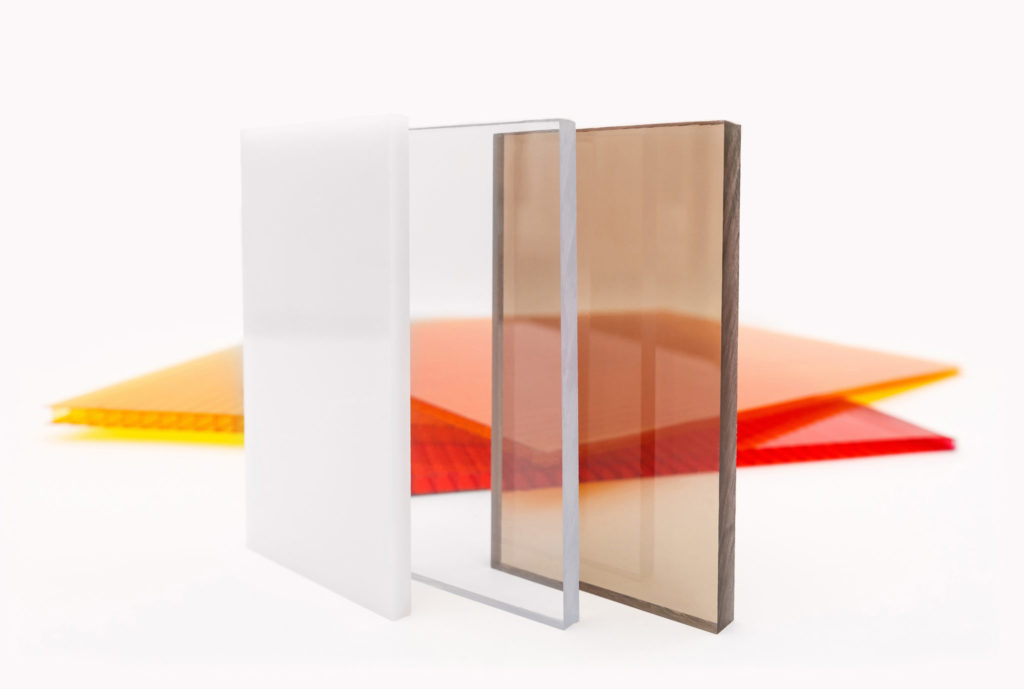

Plastic UV protection is a method that employs specific chemicals to defend against UV radiation. They shield polymer goods from photodegradation, which is the yellowing or whitening of the plastic materials, which leads to brittleness or proneness to breaking. Some of the most prevalent methods of UV protection include the following:

1. Coating

Coating polymers with an inert substance is one of the simplest and most successful techniques of UV stabilization. For example, the additional layer protects the chemical and structural integrity of the polymer resin by preventing damaging radiation from flowing through and degrading the bonds.

2. Absorption

For some polymer materials, a coating may not be a practical solution. In those cases, most turn to the method of absorption, which is the process through which plastic additives are added to polymer resin. It captures and dissipates the incoming UV radiation. It then transforms it into heat, safeguarding the polymer bonds. Benzotriazoles, Benzophenones, and HALS are the common families of UV absorbers.

3. Base Particle Scavengers

Scavengers are individual base particles that help polymer resins trap highly charged free radicals. Fortunately, they aid in preventing additional damage to the polymer chains. Scavengers have the added benefit of binding additives to the polymer at a microscopic level, preventing any damage to its structural integrity.

4. UV Stabilization Products

UV stabilizer compounds are another well-known plastic UV protection method. The energy from UV rays is dispersed in the same way that it’s absorbed. Instead of absorption, stabilizers utilize chemical mechanisms to achieve this goal and protect the carbon bonds against destruction.

5. Quenchers

Quenchers are also a type of plastic UV protection additive. Even though they operate as energy transfer carriers, they effectively move energy away from polymer chains and onto themselves.

Whatever material you choose, investing in plastic UV protection can save you thousands in the long run. You’ll increase the stability of your plastics and prolong the life of their polymers.

Do you need UV-protected plastics?

Contact Phoenix Plastics today to learn more!