As long as plastics are used, additives will be an important consideration as they can impact the success of the material. Yet, most manufacturers of plastic materials will find that all additives are not created equal, and this is especially evident with blow molding. At Phoenix Plastics, we pride ourselves on only offering the highest quality additives so you can rely on the finished product to perform as expected every time.

Phoenix Plastics Blow Molding Additives

Have you been struggling to find a plastics additives company that really understands your needs? With Phoenix Plastics you won’t have to struggle anymore. We are familiar with the need to use parison stabilizers and process enhancers to reduce the build-up of dyes, shutdowns, and purges. We have the experience needed to ensure that the process runs smoothly and the end product not only meets but exceeds the expectation.

Our blow molding additives include a variety of options, including:

- Process Aids

- Purge

- Stabilizers

- Chemical Foaming Agents

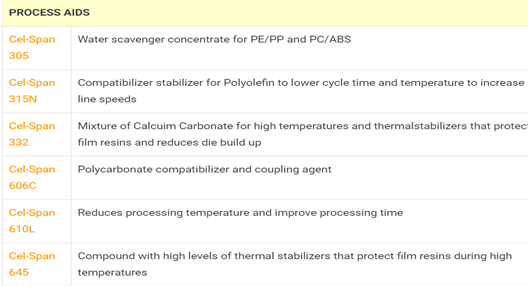

Process Aids

For blow molding, we offer a variety of process aids. If you aren’t sure which is the best for your application, you don’t have to worry! We can help you determine which is the best option for your use.

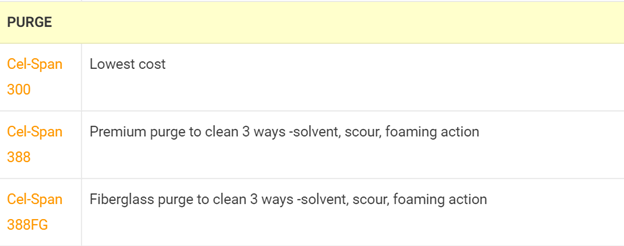

Purge

At Phoenix Plastics, we will listen to your suggestions and discuss which of these additives are needed for your specific needs.

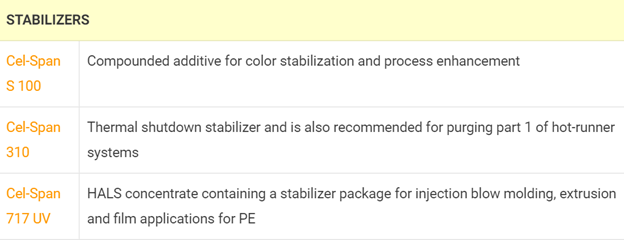

Stabilizers

Stabilizers are an important part of plastics manufacturing. Our offerings include:

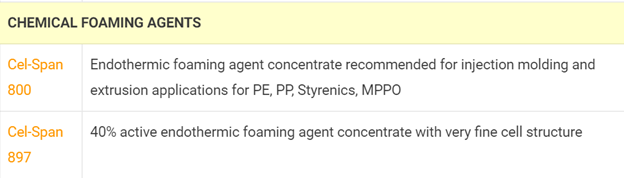

Chemical Foaming Agents

In addition to the other additives, we also offer chemical foaming agents. Like our other products, we do not expect you to know which of these is best for your use, although we are always open to your input. We can help guide you in making the decisions that will benefit your end product.

Blow Molding Additives from Phoenix Plastics

For years Phoenix Plastics has been assisting our customers with the additives that they need for their specific applications. If you want the best, you have to work with the best! Contact us today so we can discuss your specific needs. We look forward to the opportunity to exceed your expectations.