Manufacturers who work with plastic materials rely on plastic additives for various purposes. The ultraviolet (UV), thermal, and anti-oxidant stabilization properties of plastic additives provide cost-effective solutions to plastic protection. They prolong the life of polymers in various plastics by protecting them from degradation in unfavorable environments. Here are the protective benefits of Phoenix Plastics’ UV, thermal, and anti-oxidant stabilizers.

Consider These Plastic Additives for Maximum Protection

Phoenix Plastics offers stabilizers that protect polymers from the harshest conditions. Below, manufacturers and other industrial companies can find which plastic additive products work best for their polymer protection needs.

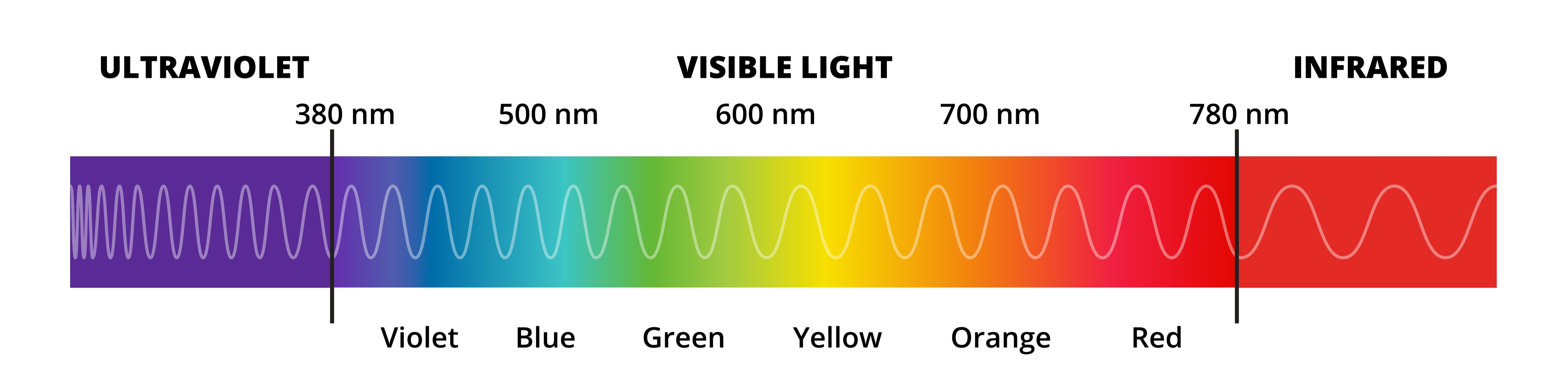

UV Stabilization

Prolonged sun exposure shortens the lifespan of plastics. Over time, UV rays damage plastic by causing photooxidation. Surface polymers break down, resulting in color fading and material degradation.

The Cel-Span UVS 717 offers maximum UV protection that extends the life of plastics by 5-10 years. It contains Hindered Amine Light stabilizers, which continually repopulate themselves while providing UV stabilization to polyolefins. This product is made from polyethylene and polypropylene resins. It is best applied to injection molding, blow molding, film, and sheet. The Cel-Span UVS 717 offers maximum UV protection that extends the life of plastics by 5-10 years. It contains Hindered Amine Light stabilizers, which continually repopulate themselves while providing UV stabilization to polyolefins. This product is made from polyethylene and polypropylene resins. It is best applied to injection molding, blow molding, film, and sheet.

Thermal Stabilization

Heat is one of the leading causes of polymer degradation in plastics. If plastic items are stored near heat-generating equipment, in the sun, or in other high-temperature environments, they will likely become prone to the breaking or cracking of the polymer molecular chains. This, in turn, leads to crosslinking and visbreaking, as well as the loss of physical properties.

Don’t let your plastics lose their form and strength in high-temperature environments. The Cel-Span S 310 thermal stabilizer contains compound antioxidants in its HDPE & LLDPE blends for maximum thermal stabilization. This plastic additive has a melting point of 190 degrees Celsius, making it perfect for molding, extrusion, and shutdown purge.

Anti-Oxidant Stabilization

Storing plastics out of the sun and away from high-temperature environments doesn’t always provide protection. Other factors, such as moisture, chemical exposure, and oxidation, often cause polymers to lose their physical integrity.

Consider the Cel-Span S 100’s anti-oxidant stabilization capabilities for plastic manufacturing and moderate-temperature storage. This plastic additive enhances the color of plastics and improves polymer durability. Made from polyolefin resins, it is ideal for extrusion and compounding.

Our Plastic Additives Company Offers Top Quality Protection

So, now you know which plastic additives best suit your needs. Our plastic additives company has offered more than 200 top-quality products to our clients since 1996.

Make an investment in your plastics today. Contact Phoenix Plastics for a free demo.