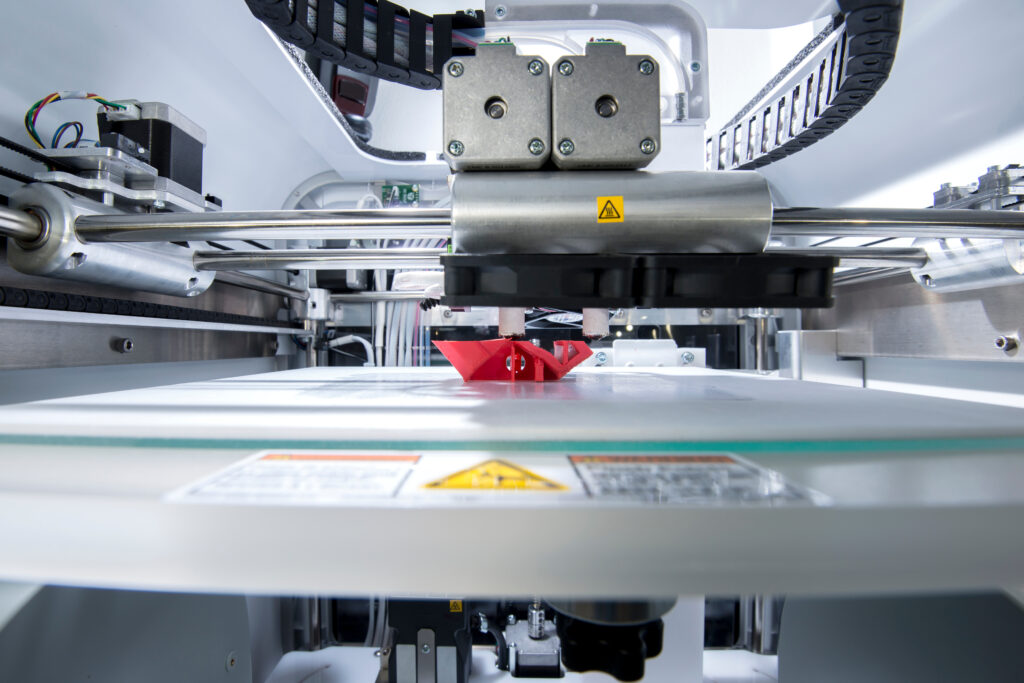

Plastic additives play a crucial role in enhancing the performance and functionality of 3D printing materials. These additives are incorporated into the plastic filaments or resins used in the 3D printing process to improve various properties and address specific requirements. Here are some of the types of plastic additives used and the benefits of using plastic additives in 3D printing.

Role of Plastic Additives in 3D Printing

Plastic additives are significant in 3D printing, just as in other plastic manufacturing processes. Incorporating plastic additives in 3D printing serves the purpose of modifying its properties to suit various applications.

Including specific additives can enhance the workability of plastic, making it easier to handle during the 3D printing process. Additionally, certain additives contribute to improving the visual appeal of the final printed product. The selection of additives depends on the specific requirements and desired outcomes of the printing project.

Expanded Role of Plastic Additives in 3D Printing

Plastic additives not only enhance the mechanical and visual properties of printed objects but also address challenges inherent to the 3D printing process. For instance, they can improve layer adhesion and reduce common issues like warping or cracking during printing. This is particularly important for materials like ABS, which are prone to warping due to their high thermal contraction rates. Additionally, the incorporation of additives allows for greater customization, enabling manufacturers to tailor materials for specific applications, such as creating flexible parts with thermoplastic elastomers or rigid components with reinforced polymers.

Types of Plastic Additives for 3D Printing

There are several common plastic additives in 3D printing, including:

Plasticizers

Plasticizers make plastics softer and stretchable, making it easier to mold plastics into the right shape during the 3D manufacturing process.

UV Stabilizers

UV Stabilizers make plastics resistant to sunlight, stopping damage and fading over time.

Flame Retardants

Flame retardants make plastics less flammable. They are required in many states to reduce fire hazards.

Colorants

Colorants are the most common additive for 3D printing plastics, changing the final product’s color.

Additional Types of Plastic Additives

Beyond the commonly mentioned plasticizers, UV stabilizers, flame retardants, and colorants, other specialized additives play a significant role in 3D printing:

- Antioxidants: These prevent degradation caused by heat and oxygen during the printing process, ensuring consistent material performance.

- Impact Modifiers: These enhance the toughness of brittle plastics like PLA, making them suitable for functional parts that require durability.

- Reinforcing Agents: Additives like glass fibers or carbon fibers increase the strength and stiffness of printed parts, making them ideal for engineering applications.

Benefits of Plastic Additives in 3D Printing

Plastic additives make a big difference in the quality of your 3D-printed products.

The use of plastic additives in 3D printing offers several benefits, including:

- Enhanced Mechanical Properties: Plastic additives enhance mechanical properties, making the printed parts more resistant to impact, bending, or deformation.

- Improved Printability: Additives reduce issues like warping, shrinkage, or nozzle clogging.

- Increased Heat Resistance: Additives, like heat stabilizers or flame retardants, enhance the heat resistance of printed objects.

- Enhanced Aesthetics: Additives improve the visual appeal of 3D-printed objects by enhancing their surface finish, color, or transparency.

- Functionality and Specialized Properties: Conductive additives can create printed parts with electrical conductivity, while antimicrobial additives can provide resistance to bacterial growth.

- Customization and Material Diversity: Different additives can be added to base plastics, enabling various material properties and applications.

Applications Enabled by Plastic Additives

The versatility provided by plastic additives has expanded the use cases for 3D printing:

Consumer Goods: Enhanced aesthetics through colorants and surface finish modifiers make 3D-printed items more appealing to end-users.

Medical Devices: Antimicrobial additives ensure hygiene in medical tools and implants.

Aerospace and Automotive Parts: Reinforced plastics with flame retardants meet safety standards while maintaining lightweight properties.

Future Trends in Plastic Additives for 3D Printing

As additive manufacturing evolves, so does the demand for advanced plastic additives. Innovations like conductive fillers are enabling the creation of electronic components directly through 3D printing. Similarly, biodegradable and recyclable additives are gaining traction as industries prioritize sustainability. Furthermore, advancements in nanotechnology are paving the way for nanocomposite additives that significantly enhance material properties without compromising printability.

3D Printing and Additive Manufacturing with Phoenix Plastics

Rely on Phoenix Plastics’ expertise for all your plastic additives needs. Contact us today to request a quote before embarking on your next 3D printing project.