Flame retardants are in many consumer products. These are chemical compounds added to a variety of materials that help prevent or limit their combustibility. Adding these types of chemicals during the manufacturing process slows the spread of fire from consumer goods.

Consumers rarely hear of or see the flame retardants that are in everyday products. However, chemical flame retardants protect lives in a variety of areas. For example, the US Fire Administration keeps statistics on fires and fatalities. Their most recent report stated that from 2017 to 2019, an estimated 2,770 residents died annually in residential fires. That’s about 8,310 lives lost over the span of those three years. Flame retardant use is essential in reducing these numbers.

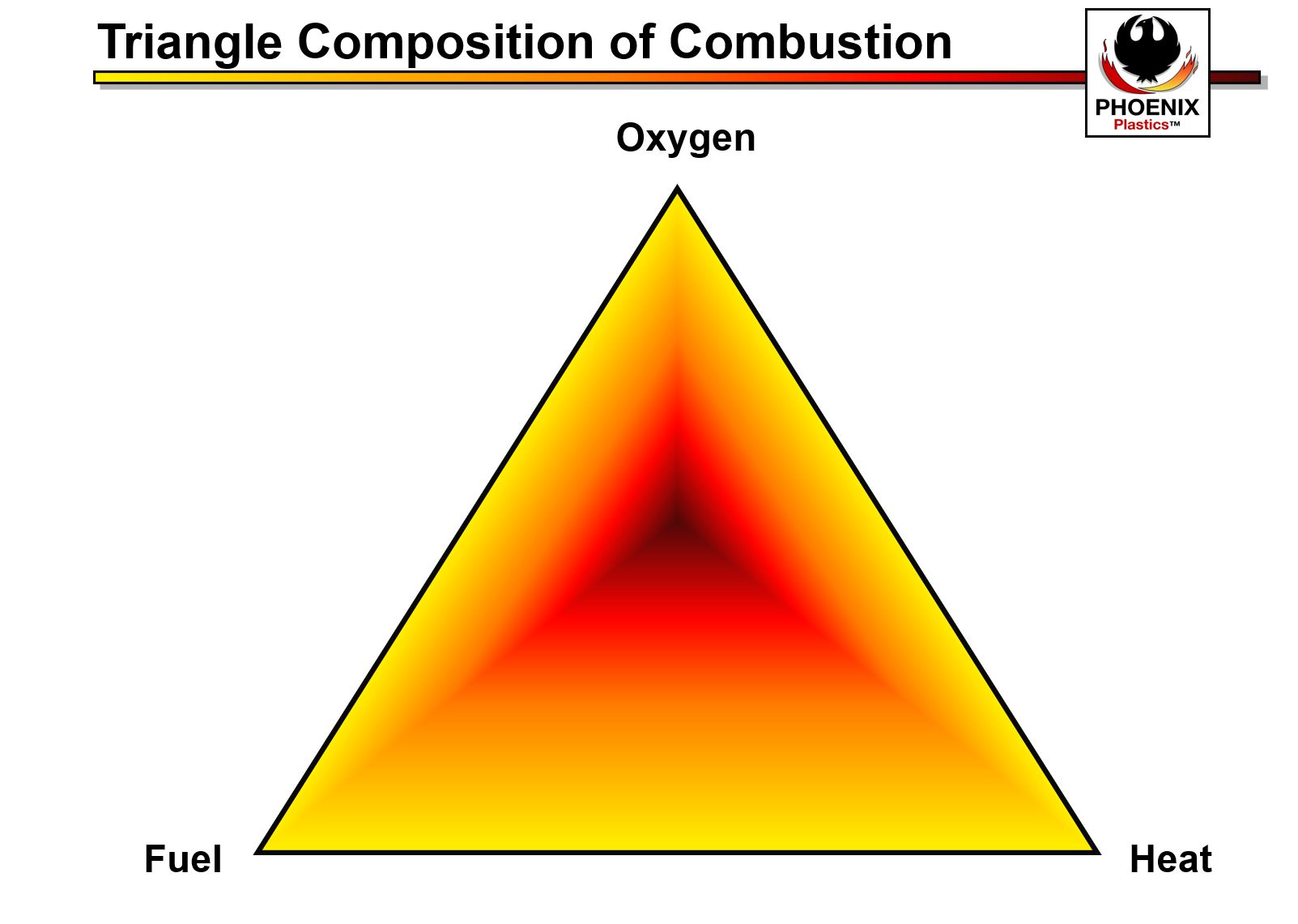

The Triangle Composition of Combustion

To achieve combustion in any polymer compound you need three requirements known as the Triangle of Fire. If the flame retardant system recommended (resin, application, and part requirement such as UL94) removes any one of these three requirements of the fire triangle then you cannot achieve combustion.

The 3 Classical Flame Retardant Systems

1) GAS PHASE is based on chlorine bromine antimony trioxide plus the resin carrier

2) SOLID PHASE systems are based on organic phosphates plus charred formation additives

3) HEAT ABSORBING systems are based on magnesium hydroxide, aluminum trihydrate, and charred forming additives

Phoenix Plastics understands these 3 classical systems. We can design and recommend a product for your specific application to achieve the most effective and economical product.

Flame Retardants in Consumer Products

Imagine what the numbers of residential fire deaths would look like if flame retardant chemicals did not get used in residential products. Fortunately, many consumer products have been using flame retardant for several decades. Chemicals, like flame retardants, give essential fire protection to businesses and residences. In addition, it reduces the mortality rate in residential fires.

Flame retardants are added to products at the manufacturing level. These chemicals can be added to plastics, wood, and other material, making flame retardants easy to include in virtually any consumer market.

Some major industries that rely on flame retardants to add safety to their products are:

- Household Goods and Furnishings: Furniture is often treated with flame-resistant chemicals to slow or inhibit fire. Most items are treated for residential use, including mattresses, couches, curtains, tables.

- Electronics: Flame retardants are essential to the plastic coatings that encase wiring in our buildings, homes, and electronic devices. Today’s consumers have more electronics than at any time in history, which means homes and businesses have more wiring than ever before.

- Construction: Lumber used in construction is treated with flame retardants before use.

- Transportation: From the wires to the foam in the seats, automobile safety increases due to flame retardants.

The addition of chemical flame retardants applied to consumer products is to industry and government standards. Some products are even required to have them.

To back up its efficacy, the number of fires that started from upholstered furniture since retardants were first added has dropped more than 80% since the early 1980s. Adding these flame-resistant chemicals to other household goods like plastics also had an impact.

Find out more about flame retardants for use in your manufacturing facility or ask questions concerning a process issue by contacting Phoenix Plastics, a leader in plastic additives, for solutions.