Plastics impact every aspect of modern life, and several industries depend entirely on plastics in their daily operations. Plastic additives are used to design plastics for their particular end-use, preventing the materials from being brittle and hard at low temperatures or soft and sticky at higher temperatures. According to Science Direct, flame retardants accounted for 35% of all plastic additive consumption worldwide.

Plastic Additives: Essential Components for Versatile Solutions

Plastic’s versatility and adaptability make it indispensable. However, raw plastics often lack the properties needed for specific applications. This is where plastic additives come in. These essential components are used to enhance the performance of plastics, tailoring them for particular end-uses. They prevent plastics from becoming brittle and hard at low temperatures or soft and sticky at higher temperatures, ensuring durability and reliability across diverse environments.

Antimicrobials/Biostabilisers

Antimicrobials ensure that plastic materials don’t deteriorate if microbes attack a portion of them. Such assaults can result in staining, discoloration, odor, and aesthetic loss. Still, more crucially, they can cause the material to lose its mechanical qualities and ability to act as an electrical insulator.

Antioxidants

Antioxidants help stop ‘oxidation,’ which happens when an oxygen-reactive polymer forms. Producing plastics at high temperatures or exposing them to UV radiation, antioxidants aid in preventing thermal oxidation processes and light-assisted oxidation. Loss of impact resistance, elongation, surface fractures, and discoloration are all effects of oxidation.

Anti-Counterfeiting

Companies and brand owners can use various anti-counterfeiting technologies, including multilayer ones, to combat counterfeiting. Optical brighteners absorb ultraviolet light. They then re-emit the energy at a higher wavelength, typically as a blue glow, and absorb more light.

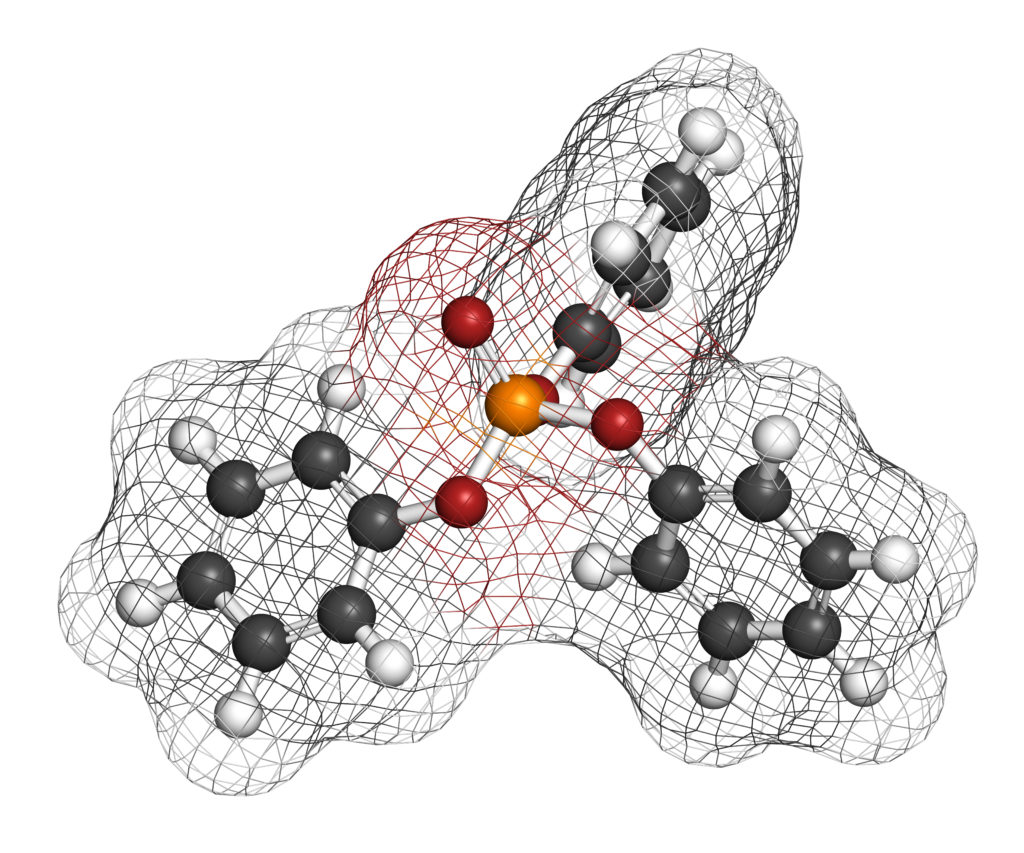

Flame Retardants

To stop the ignition or propagation of a flame within the plastic. Building, electrical, and transportation applications require plastic additives to comply with fire safety rules. One can meet these specifications by treating plastic with flame retardants.

Antistatic Agents

Plastic additives assist in preventing the accumulation of static electricity. Considering that plastics tend to be insulating, they can accumulate static charges on their surfaces, which can significantly hinder processing and be unsightly and unhygienic.

Blowing Agents

At a temperature of about 220 °C, a class of additives known as blowing agents decomposes to produce gases like nitrogen, carbon dioxide, and water. These trapped gases in the polymers turn the substance into foam, improving its insulating and energy absorption capabilities while lightening it.

Plastic additives are chemicals used to modify, process, or polymerize the end-use properties of polymers. These polymers improve these products’ durability, heat sensitivity, and strength. Various function types include processing aids, flame retardants, stabilizers, and plasticizers in various industrial applications.