If you’ve ever wondered how plastics can be molded into intricate shapes or made lighter without compromising their structural integrity, then you’re in the right place. This blog will delve into the fascinating world of chemical foaming agents, their role in enhancing the manufacturing process, and the remarkable science behind their transformative abilities.

In plastics manufacturing, chemical foaming agents come in two primary varieties: physical foaming agents and chemical foaming agents. Both agents are designed to increase the volume of plastics, making them easier to mold into complex shapes. Here is what you need to know about chemical foaming agents.

Foaming Agents Cause Chemical Reactions

Foaming agents are injected into melted plastic before forming its final shape. Physical foaming agents use high-pressure gasses to force the melted plastic to inflate and change shape or properties. Chemical foaming agents are injected similarly, but these foaming agents cause chemical reactions to change the properties of plastic.

Once injected, chemical foaming agents are heated along with the melted plastic. This causes the two materials to bond, allowing the agent to nucleate (form a molecule with the plastic as the nucleus) the plastic material and change its molecular structure. This is similar to how freezing water makes its molecules realign into ice crystals.

Key Factors that Affect the Foaming Process

The foaming process is affected by several important factors that determine the outcome of the process and what the final product will be.

These factors include:

- Temperature

- The ratio of the foaming agent to the plastic

- How well the machine mixes the two materials

- The size of the foaming agent’s particles in relation to the plastic molecules

- The melting temperature of the plastic

- How fast the foaming agent breaks down under different conditions

Applications for Chemical Foaming Agents

Chemical foaming agents can be used to accomplish several important things in plastics manufacturing.

These include the following:

Weight Reduction

Chemical foaming agents are primarily used as blowing agents, which help plastic manufacturers inject lightweight gasses into plastics. This makes plastics lighter by filling the spaces between molecules with light gas.

Weight reduction improves the usability of plastic parts, reduces shipping costs, and opens up more options for parts to be used. Machines would have more trouble operating under normal conditions if every plastic part were heavy.

Cost Reduction

Foaming plastics reduce their weight, reduce transportation costs, and reduce production costs. The more chemical foaming agents are used, the less plastic is used to form parts and products. The result is more material for making more parts or reducing the cost of producing each component.

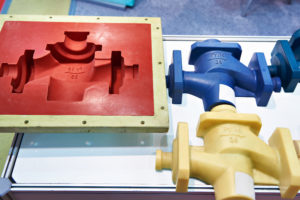

Shape Management and Molding

Chemical foaming agents play a critical role in the shaping and molding of plastics, particularly when creating complex parts with intricate geometries or internal voids. These agents are designed to release gases during the plastic molding process, which helps expand and shape the material into desired forms. This technique is especially valuable for producing lightweight, hollow, or semi-hollow plastic components that would otherwise be difficult or impossible to achieve using traditional molding methods. One of the primary challenges in plastic manufacturing is forming parts with internal spaces or voids without compromising structural integrity or precision.

For instance, components like automotive dashboards, packaging materials, or even certain medical devices often require hollow sections to reduce weight while maintaining strength and functionality. Chemical foaming agents address this challenge by introducing controlled amounts of gas into the molten plastic during the molding process. This gas creates bubbles within the material, which expand to form internal cavities or voids as the plastic solidifies.

The use of foaming agents in shaping plastics offers several advantages. First, it allows manufacturers to reduce material usage by replacing some of the solid plastic with air-filled spaces, resulting in lighter products. This not only lowers production costs but also contributes to sustainability by minimizing waste and reducing the overall carbon footprint of manufacturing processes. Additionally, the reduced weight of foamed plastic parts makes them ideal for industries like automotive and aerospace, where lightweight materials are essential for improving fuel efficiency and performance.

Learn How to Use Foaming Agents More Effectively

Chemical foaming agents can be important in changing how your company manufactures plastics and plastic parts. Before you jump into using foaming agents, spend some time learning the specifics of using foaming agents from an expert in foaming agents and other plastic additives.

Phoenix Plastics specializes in helping manufacturers improve the overall quality of their plastic parts. Contact us to discuss how our foaming agents can help you make better plastic products.