Plastics are used in countless outdoor and indoor applications, from playgrounds and greenhouses to automotive parts and packaging. As exposure to sunlight increases, so does the need to safeguard these materials against the harmful effects of ultraviolet (UV) rays. Plastic UV Protection has become a critical consideration for manufacturers and consumers alike, ensuring that products maintain their strength, appearance, and longevity over time. Without effective plastic UV protection, even the best materials can quickly degrade, leading to unwanted discoloration, brittleness, and costly replacements.

Plastic UV Protection in Modern Applications

Just like the sun can damage skin, it can also break down chemical bonding in plastics, causing the material to discolor and weaken. This is referred to as photodegradation and causes a yellowing or whitening of the material (colloquially called “chalking”). This discoloration is an indication of damage to the material, which causes a loss of tensile strength, meaning that plastics become brittle and are prone to cracking under impact or other stress. So what can you do? Here are a few of our top selections for UV-resistant plastics.

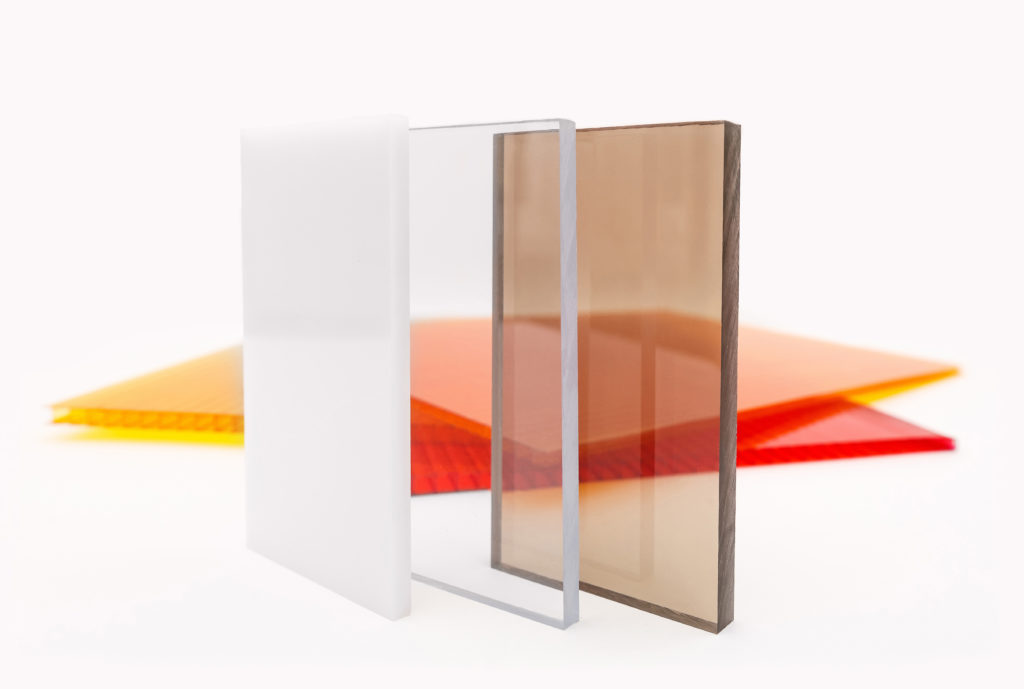

1. Acrylic

Acrylic boasts as little as 3% degradation over a 10-year period, even when used in outdoor applications. Additionally, it offers very high scratch resistance, making it an all-around excellent choice for long-term use. One drawback to acrylic, however, is its tendency to be quite brittle and prone to breaking. For this reason, it’s not recommended for load-bearing pieces or anything where long-term durability is needed. That said, it’s still a fantastic choice for a variety of applications.

2. High-Density Polyethylene

This thermoplastic is well-loved in playground equipment due to its soft but durable quality. It melts and molds easily and will not form dangerous shards when broken, unlike other thermoplastics. However, it is only marginally stronger than acrylic, making it ill-suited to high-pressure applications.

3. Polycarbonate

Polycarbonate is considerably stronger and more impact-resistant than high-density polyethylene while offering similar transparency to that found with acrylic. All of this makes it a fantastic fit for things like safety goggles, helmets, and containers. However, this increased durability also comes with a considerably higher price point, so it’s best to budget accordingly if you plan to use polycarbonate.

Why Invest in Plastic UV Protection?

Choosing plastics with built-in UV resistance or adding UV stabilizers to your products isn’t just about aesthetics—it’s about long-term value and safety. Plastic UV protection helps preserve the integrity and mechanical properties of your materials, preventing early damage and reducing maintenance costs. Whether you are producing outdoor furniture, signage, or automotive components, integrating UV-resistant options ensures that your investment stays protected against the elements. Don’t wait for photodegradation to affect your products—explore the many solutions available and make plastic UV protection a priority in your next project.

These are just a few of your options when it comes to UV-resistant packaging. Whatever material you decide on, consider that investing in plastic UV protection upfront can save you thousands in the long run.