Plastic additives improve material properties and performance of plastic materials across various industries. By modifying and improving material properties, these additives contribute to the durability, strength, flexibility, and overall quality of plastic products. In this blog, we delve into the mechanisms behind plastic additives and explore how they optimize material performance.

How Plastic Additives Improve Material Properties

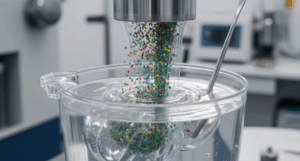

Plastic additives are substances added to polymers during the manufacturing process to alter specific properties or characteristics of the material. These additives can include fillers, reinforcements, plasticizers, stabilizers, colorants, and flame retardants, among others. Each type of additive serves a unique purpose and contributes to different aspects of material performance.

Enhanced Durability and Strength

One of the primary goals of plastic additives is to improve the durability and strength of plastic materials. Additives such as fillers and reinforcements help reinforce the structure of plastics, making them more resistant to wear, impact, and deformation. By increasing the material’s tensile strength and toughness, these additives extend the lifespan of plastic products and enhance their ability to withstand harsh environments.

Flexibility and Versatility

Plasticizers are commonly used to increase the flexibility and versatility of plastic materials. By reducing the polymer’s glass transition temperature, plasticizers improve its flexibility, making it easier to mold and shape. This property is particularly crucial in applications where flexibility and bendability are essential, such as in the manufacturing of PVC pipes, cables, and automotive components.

Stability and Performance

Stabilizers are additives designed to enhance the thermal, oxidative, and UV stability of plastic materials. These additives help prevent degradation and discoloration caused by exposure to heat, light, and oxygen, thereby improving the material’s long-term performance and appearance. Stabilizers play a crucial role in extending the service life of plastic products, especially those used outdoors or in high-temperature environments.

Color and Aesthetics

Colorants and pigments are used to impart color and visual appeal to plastic materials. By incorporating colorants into the polymer matrix, manufacturers can create products with vibrant hues and attractive finishes. Additionally, colorants can be customized to meet specific aesthetic requirements, allowing for endless design possibilities in various industries, including automotive, consumer goods, and packaging.

Flame Retardancy

Flame retardants are formulated to reduce the flammability and combustibility of plastic materials. These additives work by suppressing the ignition and spread of flames, thereby improving fire safety and compliance with regulatory standards. Flame retardants are commonly used in applications where fire resistance is critical, such as in building materials, electronics, and transportation.

Optimizing Material Performance

By carefully selecting and incorporating the right combination of plastic additives, manufacturers can optimize the performance of plastic materials to meet the demands of diverse applications. Whether it’s improving durability, enhancing flexibility, ensuring stability, or achieving specific aesthetic requirements, plastic additives play a vital role in achieving desired material properties.

Plastic Additives from Phoenix Plastics

Plastic additives are indispensable tools for optimizing the performance of plastic materials across various industries. From enhancing durability and strength to improving flexibility, stability, and aesthetics, these additives offer a multitude of benefits that contribute to the quality and functionality of plastic products. By understanding how plastic additives improve material properties, manufacturers can innovate and create superior products that meet the evolving needs of consumers and industries alike.

Unlock the full potential of your plastic products with Phoenix Plastics’ advanced additives. Contact us today to learn how our solutions can enhance your materials’ performance, durability, and quality.