Top Plastic Additive Trends: What’s Shaping the Industry Today?

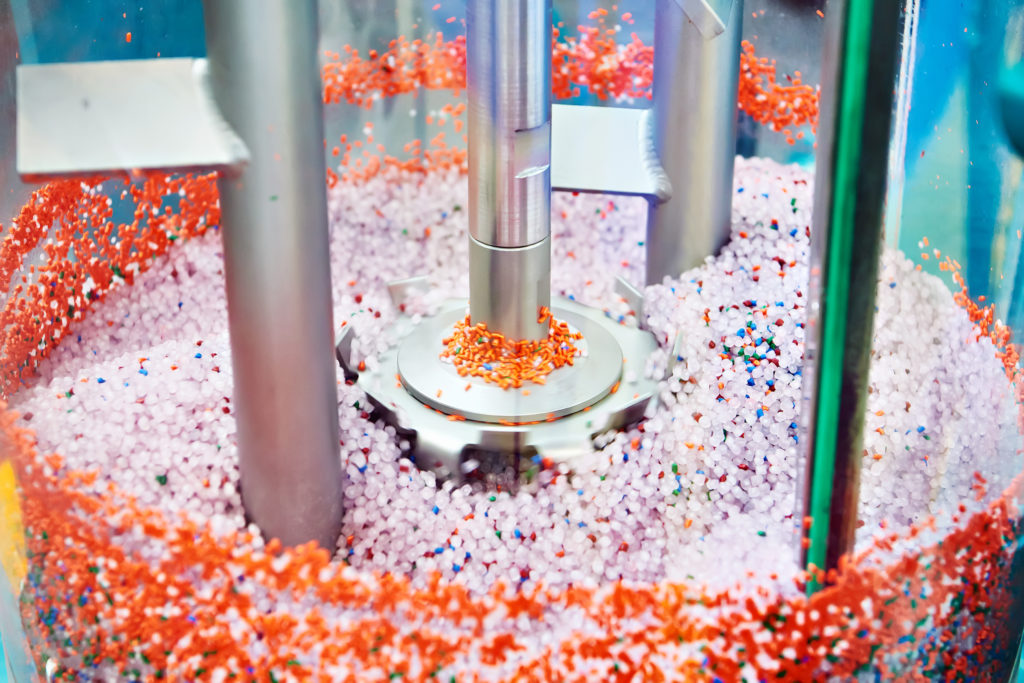

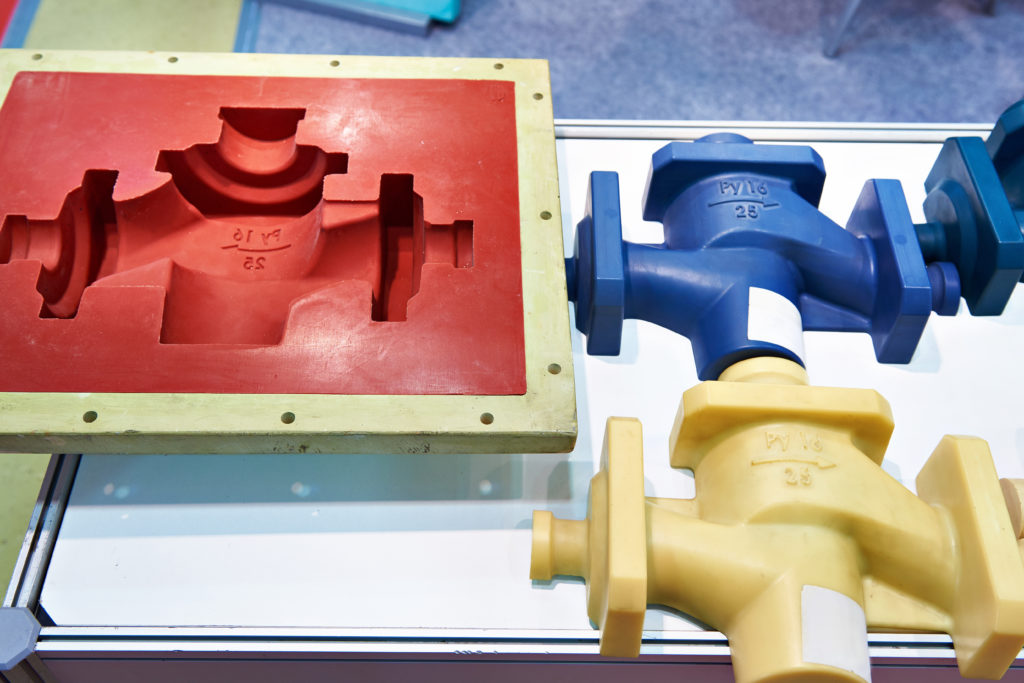

In 2026, plastic additive trends are shifting toward solutions that reduce environmental impact while improving performance, not just meeting minimum compliance. Processors increasingly look for plastic additive trends that support recyclability, lighter-weight parts, and lower VOC and toxicity profiles to satisfy brand, regulatory, and customer expectations. At the same time, plastic additive trends emphasize higher …

Top Plastic Additive Trends: What’s Shaping the Industry Today? Read More »