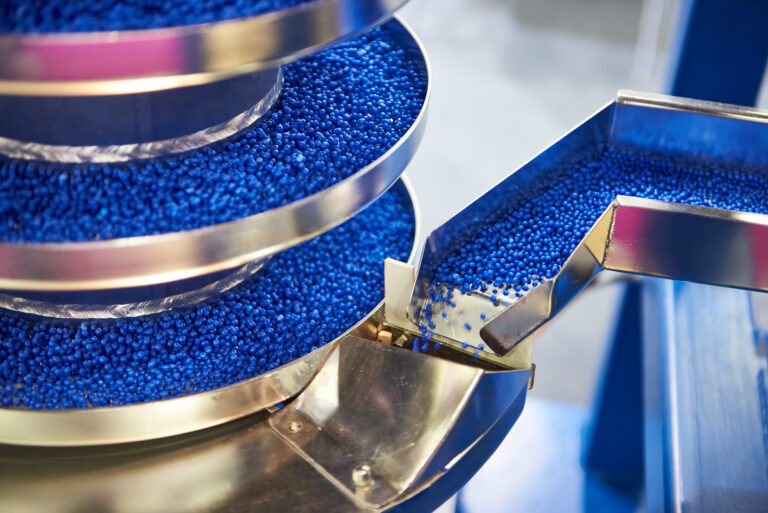

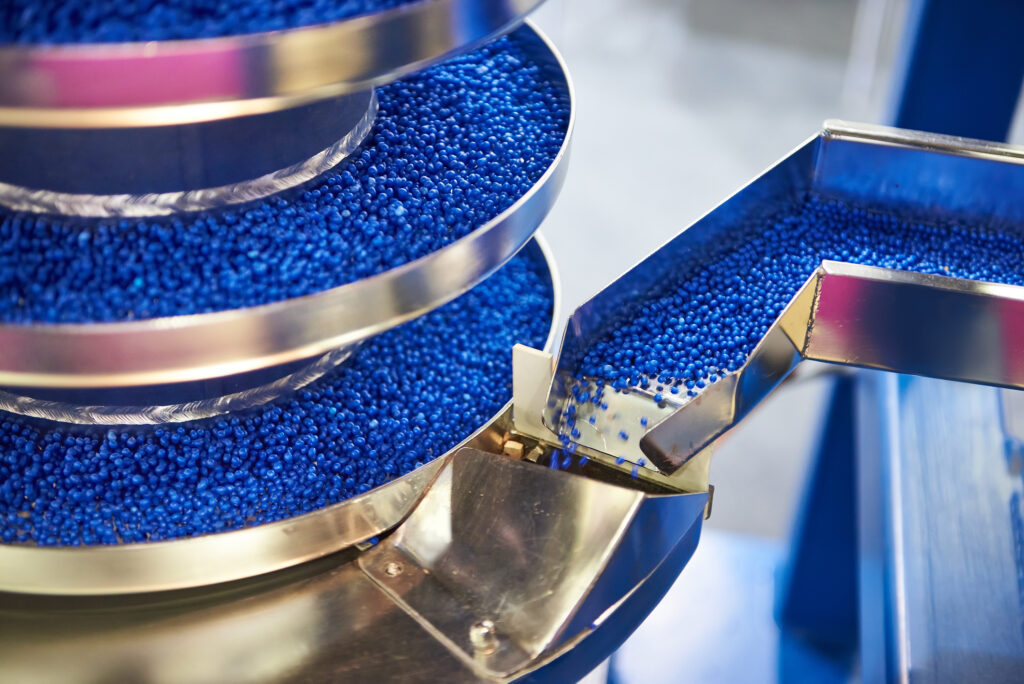

Stabilizers are an important part of plastics manufacturing. Stabilizers are an additive that makes plastics safer, more durable, and more useful for different use cases. Before you develop new plastic products, it’s essential to understand the importance of stabilizers in plastic manufacturing.

Purpose of Stabilizers in Plastics Manufacturing

Stabilizers are used across the plastic industry because they are a necessary part of making plastic withstand different conditions. Plastic may seem like a solid material that can do a lot on its own, but plastics are susceptible to other chemicals and UV radiation.

Think about the last plastic item you left outside that is not meant to be outside. It likely faded in color and started to melt. UV radiation from sunlight can do this to plastics without UV stabilizers. Other chemicals can cause plastics to degrade as well. Adding suitable stabilizers can reduce the impact on plastic, making it last much longer.

Types of Stabilizers

Several types of stabilizers are commonly used across the plastic industry. These include:

Antioxidants

When exposed to oxygen, many things naturally start to break down, and this is usually because of the development of bacteria that slowly eats away at materials. Antioxidants stop plastics from oxidizing or reacting to oxygen and stop bacteria growth. The right combination of antioxidants can keep bacteria from destroying plastics over time.

Antioxidants are additives that inhibit the oxidation process, which is the reaction of plastics with oxygen. They effectively prevent the formation of free radicals, which are highly reactive and can initiate chain reactions that break down the polymer chains. By interfering with these reactions, antioxidants prevent the degradation of plastics and maintain their physical and chemical properties.

UV Stabilizers

UV stabilizers neutralize UV radiation, which usually comes from sunlight. Plastics left outside should have UV stabilizers to slow or prevent the sun’s impact. That way, plastic parts stay in good shape for much longer.

Plastics that are used outdoors or exposed to sunlight for extended periods of time are particularly vulnerable to degradation. The effects of UV radiation can cause discoloration, cracking, and deterioration of material properties, leading to potential safety risks and reduced product lifespan.

Thermal Stabilizers

Thermal stabilizers are similar to UV stabilizers but help plastics handle different temperatures instead of sunlight. The right thermal stabilizers can make plastics durable in freezing temperatures or under boiling heat, and it all depends on the mixture of the additives.

The right combination of thermal stabilizers can enhance the thermal stability of plastics and enable them to remain durable and reliable in extreme temperature conditions. Different thermal stabilizers offer varying levels of protection and performance, depending on the specific temperature range and application requirements.

Lubricants

Lubricants are widely used in plastics manufacturing because they prevent wear on machines and make plastics easier to work with. They reduce friction between the plastic and other objects, like machinery or the plastic itself. That way, it becomes easier to shape and move through machinery without damaging anything along the way.

Benefits of Stabilizers in Plastics Manufacturing

You can find plastics with stabilizers in any part of the plastic manufacturing industry since they are so beneficial. Using the right combination of stabilizers can help companies save money while extending product life. They can even keep parts from breaking down in difficult conditions, making them more reliable and useful. Make sure that the plastic that you use has the right additives for your applications.

Find the Right Plastic for Your Needs

There is a plastic with stabilizers for every use case; you just have to find the one that fits your needs. Contact us now to get a quote for plastic or plastic manufacturing services from Phoenix Plastics.