Plastic additives play a crucial role in the thermoforming process, enhancing the performance and properties of plastics to meet the requirements of finished products. These additives are incorporated into the plastic material during manufacturing and can provide various benefits. Here are some key points to know about the use of plastic additives in thermoforming.

What is Thermoforming?

Thermoforming is a technique used to shape plastic by applying heat and suction around a mold. A plastic sheet is heated until it becomes pliable and stretched into a thin sheet, sometimes with additives that enhance elasticity. The heated sheet is then positioned over a mold, and a combination of heat and suction is applied to pull the sheet down and conform it to the shape of the mold. Once the plastic reaches the appropriate temperature, it effectively stretches onto the mold, taking on its shape. Subsequently, the plastic cools and solidifies, resulting in the final product with the desired shape.

Types of Plastic Additives Used in Thermoforming

Thermoforming plastic can require several additives. Some of your options are:

Fillers

Fillers are used to increase the volume of plastic without using large amounts of precious materials. They can make plastic lighter, more durable, and more stable, and have other benefits based on which fillers are used.

Stabilizers

Stabilizers help keep plastic stable under different conditions and make it less likely to react to other chemicals, making plastic safer and more durable. Certain stabilizers may be required by law depending on the product being made and where it will be sold.

Lubricants

Lubricants reduce friction between the plastic, mold, finished product, and other surfaces, making it easier for the plastic to slide over surfaces or through machinery. Manufacturers use lubricants on particularly tough or sticky plastics so that they are easier to work with in machinery like thermoforming machines.

Elastomers

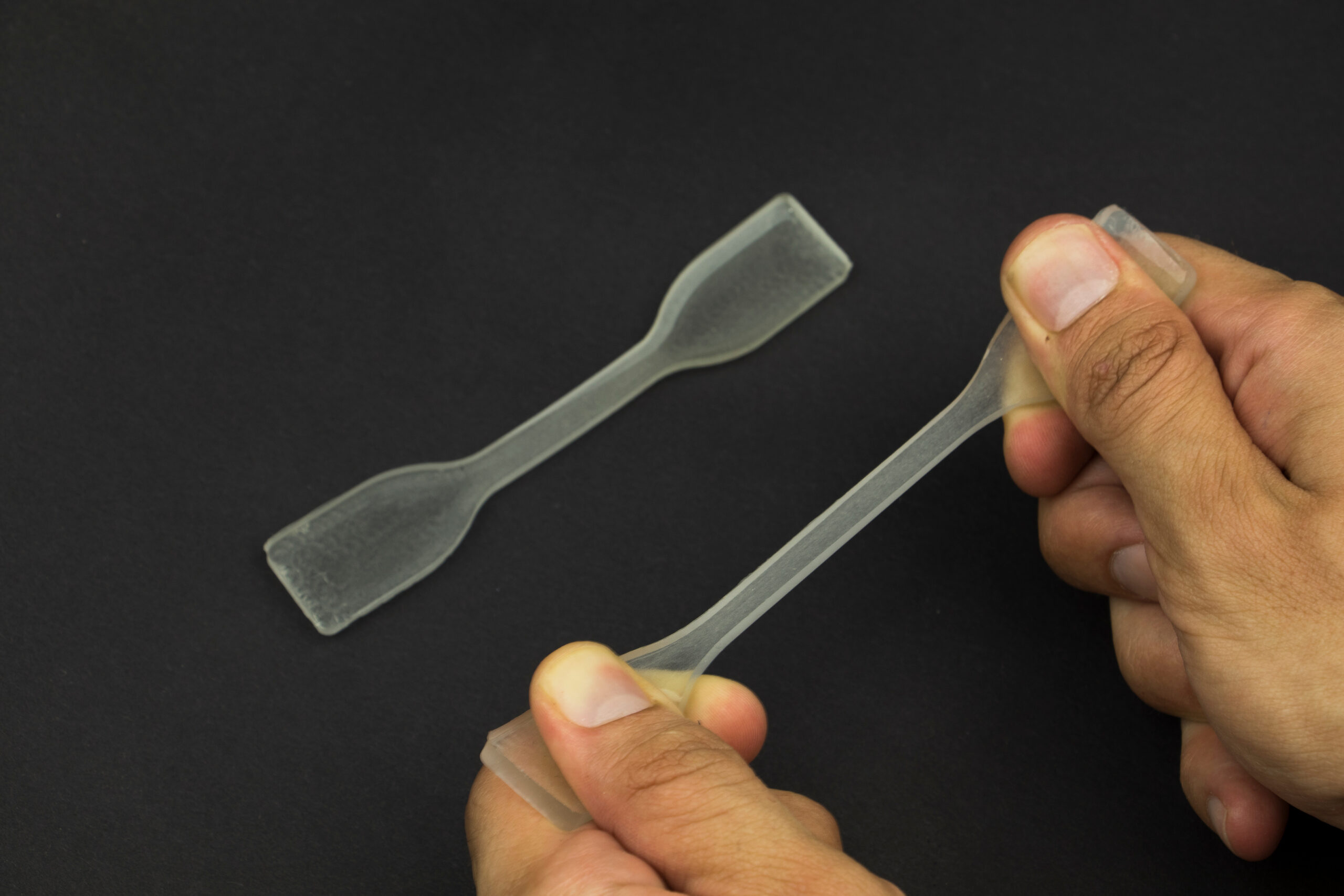

Elastomers are used to make plastic more elastic. These are essential additives in thermoplastics since they allow the sheet of plastic to stretch around the mold rather than just melting when heated. Balancing the level of elastomers in thermoplastic is important since too much can make it too stretchy, while not enough makes it hard to form.

Get Better Thermoplastics For Your Next Project

Selecting the appropriate thermoplastics is crucial to ensure optimal quality and value in your thermoforming process. For a quote for your next batch of thermoformed plastic products, contact Phoenix Plastics, and our expertise will provide valuable insights and assistance tailored to your specific requirements.