During the last couple of years, the market has seen increased activity in a new class of anti-corrosion plastic compounds called VCI (Volatile Corrosion Inhibitors). These new products were developed according to environmental standards. VCI today represents the most economical avenue in combating atmospheric corrosion damage to metals. It is estimated that in the US alone, the direct cost of atmospheric corrosion to industry, government, and consumers is around 20 billion dollars.

How Volatile Corrosion Inhibitors Work:

Volatile corrosion inhibitors like Phoenix Plastics Cel-Span 775 VCI Masterbatch work by emitting safe and almost odorless vapor molecules into the surrounding air space of the package. It takes 12 to 24 hours for the volatile corrosion inhibitor molecules to saturate the entire enclosure.

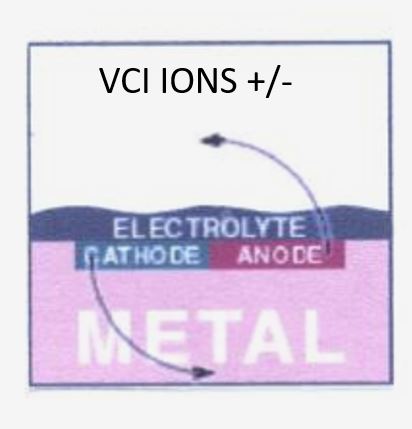

The corrosive environment, such as oxygen, heat, moisture, and pollutants within the enclosure, will cause the molecules to hydrolyze into VCI protective ions. The VCI ion then attaches itself to the metallic surface that is in the enclosure and thus protects it from corrosion.

Advantages of using Cel-Span 775 VCI:

VCI is commonly used across many industries today to prevent expensive metal parts and components from corrosion. VCI can reduce labor time, provide equipment protection, and reduce costs.

Industries utilizing the benefits of volatile corrosion inhibitors

- Automotive (CEL-SPAN 775 meets Volkswagen Auto Spec)

- Aerospace

- Military (CEL-SPAN 775 meets Military Spec)

- Electronics

- Packaging

- Heavy Equipment

- Pipeline

- Mining

- Steel

Cel-Span 775 VCI can be used to produce the following types of film products:

- VCI film and bags

- Stretch film

- Shrinkable film

- Foamed PE

- Zip-Lock bags

- Emitters

Corrosion to industry, government, and the public sector costs billions of dollars per year in equipment failures, product rejects, audits, and a shorter life span of the products. By using Cel-Span 775 VCI technology, it can help greatly to reduce these costs, conserve resources, and extend the life of metal parts. More and more film companies and producers of film products are becoming aware of this VCI protection and are now investigating and implementing these novel products in their various forms to be used for the preservation of their products.

It’s hard to argue against the value of using vapor corrosion inhibitors.

Customers wondering where to buy VCIs do not need to look any further. Phoenix Plastics has your VCI needs handled.