The Impact of Plastic Additives on Recycling

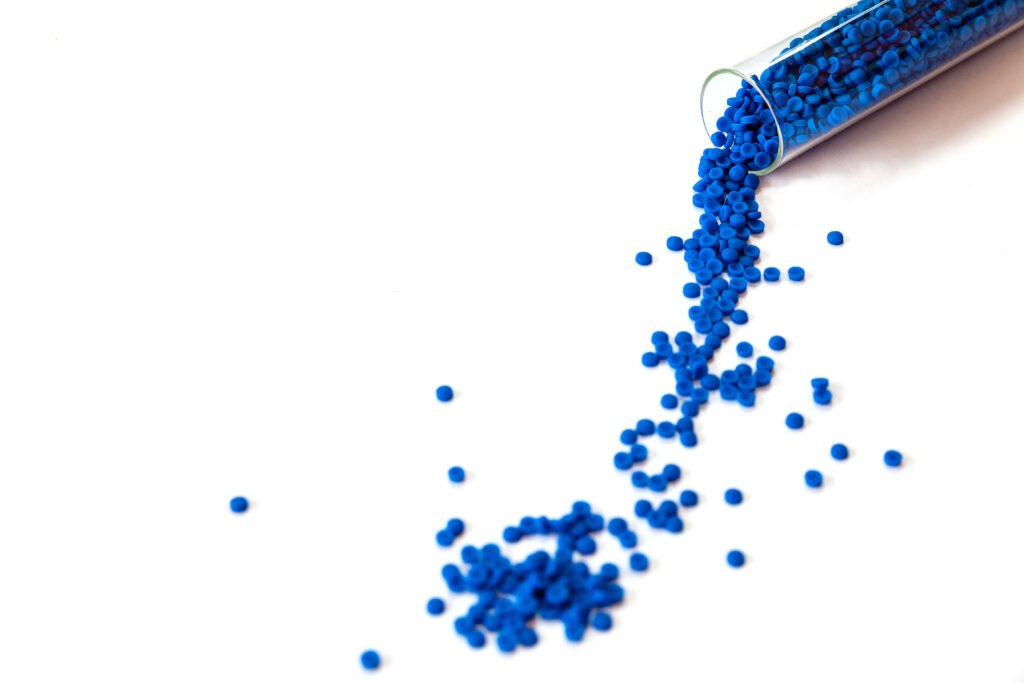

One factor affecting plastic recycling is the presence of plastic additives. Plastic is one of the most widely used materials in the world, and recycling is one of the ways to reduce plastic waste, but it is more complex than it seems. Plastic recycling faces many challenges, such as the diversity of plastic types, the …