The Role of Additives in Lightweight Plastics: Reducing Weight While Retaining Strength

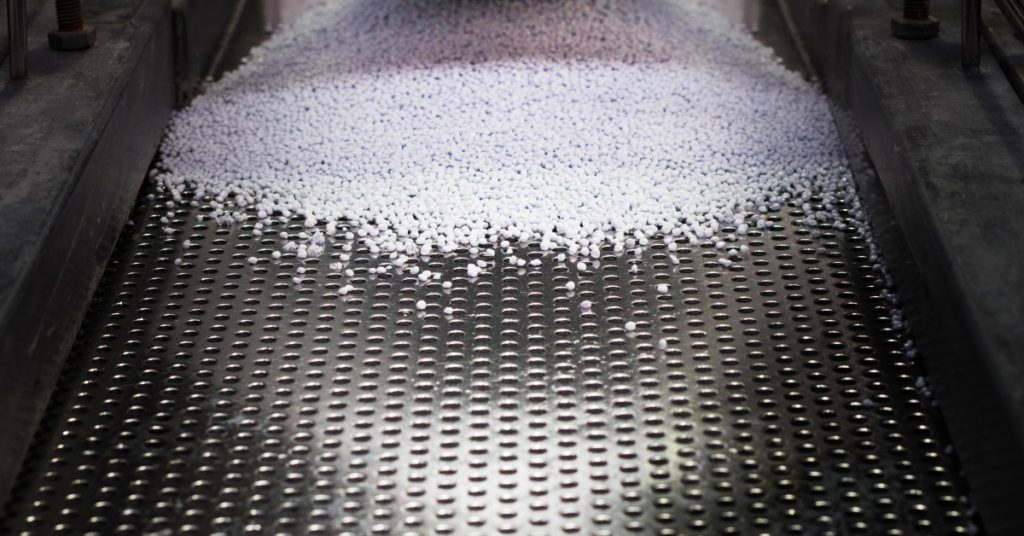

The demand for lightweight plastics has never been greater. From automotive components to consumer electronics, industries across the board are searching for ways to reduce material weight without sacrificing structural integrity. The solution lies in a sophisticated blend of polymer science and advanced additive technology. At Phoenix Plastics, we’ve spent decades perfecting the art of …

The Role of Additives in Lightweight Plastics: Reducing Weight While Retaining Strength Read More »