Desiccants in Plastic Manufacturing

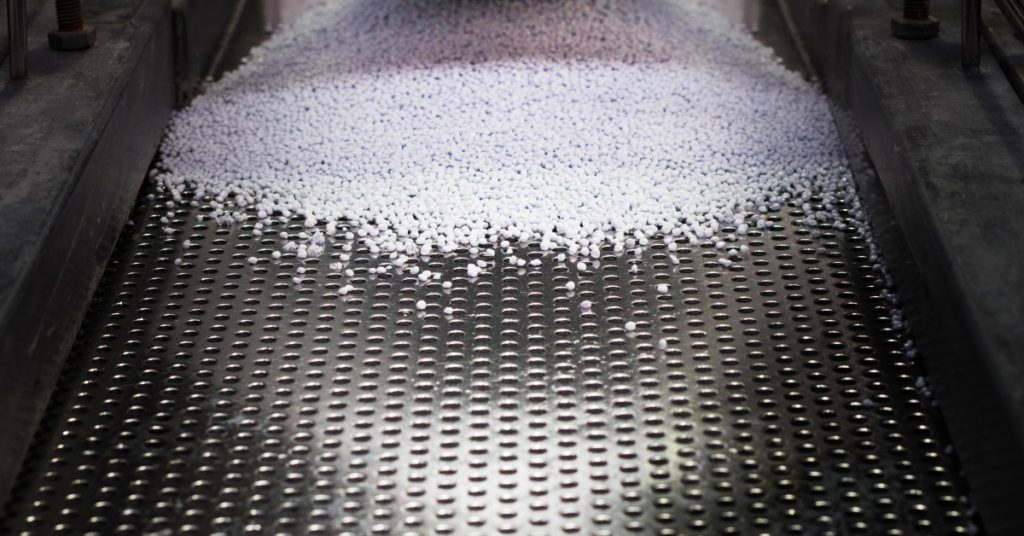

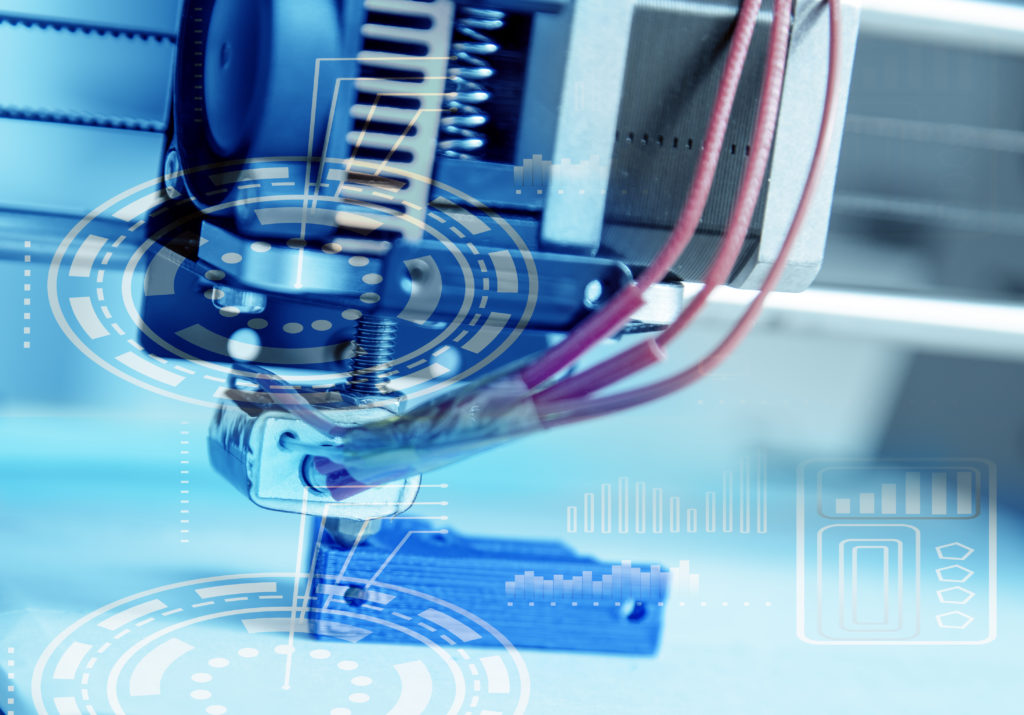

Desiccants play a crucial role in ensuring the quality and durability of plastic materials. Plastic is a mainstay in our society, used in an infinite number of products and applications. Plastics are formulated for their intended use. However, plastics may contain water formed in high-temperature molding, and the water bubbles can cause holes and other defects, …